Boiler Efficiency: The Impact of System Water Quality

Boiler efficiency, vital in residential settings for its impact on energy costs and environmental footprint, reflects a boiler’s ability to convert fuel to heat. This efficiency not only contributes to lower energy bills and a smaller carbon footprint but is also significantly influenced by water quality. Impurities like minerals, gases, and organic compounds in water can cause scaling, corrosion, and foaming, adversely affecting boiler performance. Therefore, understanding and managing water quality is crucial for optimal boiler efficiency.

Basics of Boiler Operations

Contents

- 1 Basics of Boiler Operations

- 2 How Water Quality Affects Boiler Efficiency

- 3 Water Treatment Solutions for Boilers

- 4 Benefits of Ensuring Good Water Quality in Boilers

- 5 Boiler Efficiency and System Water Quality FAQs

- 5.1 What Exactly is “Boiler Efficiency”?

- 5.2 How Can I Tell if Poor Water Quality is Affecting My Boiler’s Efficiency?

- 5.3 Can Regular Tap Water Be Used in Boilers?

- 5.4 How Often Should Water Quality Be Checked in Boiler Systems?

- 5.5 What Are the Long-Term Implications of Neglecting Water Quality in a Boiler System?

- 5.6 Conclusion

- 6 Call McAllister Energy For All Your Home Heating Needs

The Role of Water in Boiler Systems

Water is crucial in boiler systems, serving as a heat transfer medium to distribute energy from fuel combustion for heating or industrial processes. In steam boilers, it is heated to vaporization, producing steam for various applications.

Key Components of a Boiler System

A boiler system consists of several key components. The burner ignites the fuel in the combustion chamber, where it is transformed into heat. This heat is then transferred to water via the heat exchanger. The system also includes controls and safety devices for efficient and safe operation, while the flue stack vents combustion by-products. Each part is essential for the system’s overall functionality and efficiency.

How Water Quality Affects Boiler Efficiency

Overview of Impurities Commonly Found in System Water

Water used in boiler systems can contain various impurities that detrimentally affect boiler efficiency. These include:

- Minerals: Such as calcium and magnesium, which are often present in hard water.

- Gases: Like oxygen and carbon dioxide, which can infiltrate the system.

- Organic Matter: Which can be introduced through various sources.

- Suspended Solids: Arising from internal or external sources.

Scale Formation and Its Impact

Scale formation is a major issue in boilers, caused by the precipitation of minerals like calcium and magnesium. This process leads to:

- Formation of Scale: When these minerals settle and harden on boiler surfaces.

- Reduced Heat Transfer: Scale acts as an insulator, diminishing the efficiency of heat transfer.

- Potential for Tube Failures: Accumulated scale can lead to tube blockages and subsequent damages.

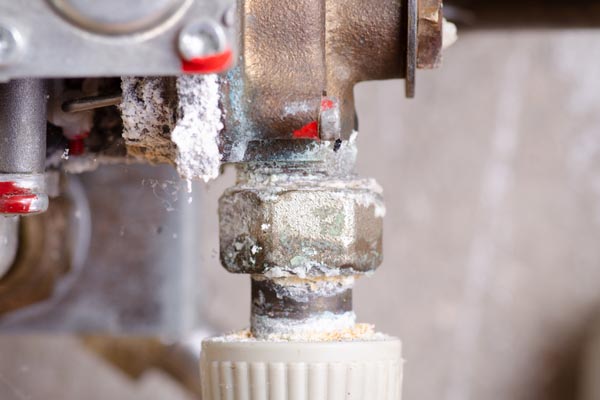

Corrosion and Its Detrimental Effects

Corrosion in boiler systems is a significant issue, arising from various factors such as oxygen ingress and pH imbalances in the water. This corrosion can weaken boiler components, leading to risks that affect both the system’s efficiency and safety. Additionally, issues related to corrosion often result in reduced boiler efficiency, further underscoring the importance of addressing these concerns promptly.

Foaming, Priming, and Carryover

While less frequent, certain issues stemming from high concentrations of impurities in water can also adversely affect boiler efficiency. These conditions often result in poor steam quality, which in turn reduces the system’s efficiency. Additionally, problems like foaming and carryover can cause damage to equipment downstream of the boiler. This not only necessitates further maintenance but also presents operational challenges.

Water Treatment Solutions for Boilers

Pre-treatment Options

Effective water treatment is crucial for maintaining boiler efficiency, and pre-treatment options play a significant role in this process. These include:

- Filtration Systems: Designed to remove particulate matter and suspended solids from water.

- Softeners and Ion Exchange: These systems are used to reduce water hardness, effectively removing minerals like calcium and magnesium.

- Deaeration and Oxygen Scavengers: Employed to eliminate dissolved gases, particularly oxygen, that can cause corrosion.

- pH Adjusters and Alkalinity Builders: These are used to maintain the correct pH and alkalinity levels in the water, preventing corrosion and scale formation.

Internal Treatment Methods

Internal treatment methods are employed within the boiler system to further protect against efficiency loss and damage. These include:

- Scale Inhibitors: Chemicals that prevent the formation of scale on boiler surfaces.

- Corrosion Inhibitors: These agents help protect the boiler’s metal surfaces from corrosion.

- Antifoaming Agents: Used to reduce foaming in the boiler, which can impact steam quality and efficiency.

- Dispersants: These help in the dispersion of suspended solids, preventing the formation of deposits.

Continuous Monitoring and Automated Control Systems

Consistent monitoring and control of water quality are essential for the long-term efficiency and safety of boiler systems. This aspect involves:

- Importance of Regular Monitoring: Continuous monitoring helps in early detection and rectification of potential water quality issues.

- Technological Advancements in Boiler Water Quality Management: Modern technologies facilitate precise and automated control of water quality, enabling more efficient and effective management of boiler systems. These advancements have significantly improved the ability to maintain optimal water conditions, enhancing overall boiler efficiency and longevity.

Benefits of Ensuring Good Water Quality in Boilers

Ensuring good water quality in boilers brings several key benefits, impacting both performance and safety.

Increased Efficiency and Cost Savings

High water quality boosts boiler efficiency, leading to lower energy consumption and significant cost savings. This is achieved by preventing common issues like scaling and corrosion, which impair the boiler’s ability to transfer heat effectively.

Extended Equipment Lifespan

Clean water reduces the risk of damaging scale buildup and corrosion, thus extending the lifespan of boiler components. This means fewer replacements and repairs, contributing to the overall longevity of the system.

Reduced Maintenance Costs and Downtime

With fewer water quality issues, boilers require less frequent servicing and experience fewer breakdowns. This reduces both the direct costs of maintenance and the inconvenience of operational downtimes.

Safety Enhancements

Proper water treatment and management significantly enhance the safety of boiler operations. By avoiding issues that can lead to leaks or explosions, good water quality ensures a safer environment for both residential and industrial settings.

Boiler Efficiency and System Water Quality FAQs

What Exactly is “Boiler Efficiency”?

Boiler efficiency is the measure of how efficiently a boiler converts the energy in its fuel into usable heat. This efficiency is typically expressed as a percentage of the total energy in the fuel that becomes heat.

How Can I Tell if Poor Water Quality is Affecting My Boiler’s Efficiency?

Indicators of poor water quality affecting boiler efficiency include reduced heating output, increased fuel consumption, and abnormal noises or operations. These symptoms suggest issues like scaling, corrosion, or other water-related problems inside the boiler.

Can Regular Tap Water Be Used in Boilers?

While it’s possible to use tap water in boilers, it may not be ideal due to potential impurities such as minerals and chemicals. These impurities can lead to scaling and corrosion, impacting the boiler’s efficiency and lifespan.

How Often Should Water Quality Be Checked in Boiler Systems?

It’s recommended to check the water quality in boiler systems regularly, ideally annually. Regular checks help in early detection and correction of any water-related issues that might affect the system’s performance.

What Are the Long-Term Implications of Neglecting Water Quality in a Boiler System?

Over time, neglecting water quality in a boiler system can result in decreased efficiency, increased repair and maintenance costs, and a shorter lifespan for the boiler. Additionally, it can lead to safety hazards such as leaks or potential failures.

Conclusion

The pivotal role of water quality in determining boiler efficiency cannot be overstated. Ensuring optimal water conditions is essential for maintaining high efficiency, prolonging equipment lifespan, and ensuring safety.

Regular maintenance, vigilant monitoring, and investment in effective water treatment solutions are key practices that should be adopted. By prioritizing these aspects, homeowners and facility managers can safeguard their boiler systems, optimize performance, and avoid costly repairs, thereby ensuring both economic and operational efficiency.

Call McAllister Energy For All Your Home Heating Needs

For all your HVAC and oil delivery needs, contact McAllister Energy. We have some of the most highly qualified and professionally certified technicians in Southern New Jersey. Each of our friendly techs can conduct all kinds of HVAC services, such as oil tank upgrades, boiler repair, ductless installations, furnace replacements, and more. We have various oil delivery plans and financing options. This way, you can customize your fuel deliveries to meet your needs. Our heating oil delivery and HVAC services are affordable and are done accurately and promptly at all times.

All of our services come with a guarantee. Our HVAC maintenance services improve your energy efficiency and home comfort while decreasing your HVAC costs. We can also assist you when you need to replace your heating and cooling system. We will help you find the best make and model for your home without sacrificing your budget. Our experts have the skills, training, and experience to ensure that all your home comfort needs are met. Book an appointment with us today. Call McAllister Energy for a free, in-home estimate.

You can click here to contact us now or call us at (856) 665-4545 to find out more! Click the link to view our service area.

Related Articles: